Your cart is currently empty!

Scientists Turn Wine Waste Into Biodegradable Plastic That Breaks Down in 17 Days

Something extraordinary happened when Dr. Srinivas Janaswamy finished his presentation about agricultural waste solutions at South Dakota State University. A colleague approached him with an idea that would transform how we think about both vineyard waste and plastic pollution. What emerged from their conversation would challenge the fundamental assumption that strong packaging materials must persist in the environment for centuries.

Hidden in the pruned canes that wineries typically burn or compost lies a material with properties that could revolutionize packaging. Scientists have discovered how to extract this resource and transform it into films that outperform traditional plastic bags while completely disappearing from soil in just over two weeks.

The implications extend far beyond laboratory experiments. With microplastics entering human bloodstreams and ocean garbage patches growing larger each year, this breakthrough represents more than scientific progress. It offers hope that humanity can escape the plastic trap it created.

Breakthrough Discovery Turns Wine Industry Waste Into Solution

South Dakota State University researchers have achieved something that seemed impossible: creating packaging material stronger than conventional plastic that completely biodegrades in 17 days. Their source material comes from an unexpected place, the woody canes pruned from grapevines each winter.

Dr. Srinivas Janaswamy, associate professor in the Department of Dairy and Food Science, leads research focused on converting agricultural byproducts into valuable materials. His laboratory has systematically explored various plant-based sources for creating biodegradable films.

Previous experiments involved extracting cellulose from avocado peels, soy hulls, alfalfa, switchgrass, spent coffee grounds, corncobs, and banana peels. Each source produced films with different characteristics, but none matched the performance achieved with grapevine canes.

The collaboration with vineyard expert Anne Fennell, Distinguished Professor in the Department of Agronomy, Horticulture and Plant Science, proved crucial for identifying grapevine canes as ideal raw material. Their partnership demonstrates how interdisciplinary cooperation can unlock solutions hiding in plain sight.

Published results in the academic journal Sustainable Food Technology validate the breakthrough’s significance for both scientific communities and commercial applications.

Microplastics Pose Unknown Health Threats to Life

Plastic breakdown creates microscopic particles that infiltrate food chains and ecosystems worldwide. These micro- and nanoplastics have been discovered in human bloodstreams, organs, and tissues, raising serious concerns about long-term health effects.

Research documents plastic particle contamination in drinking water, seafood, agricultural products, and even airborne particles that people inhale daily. The pervasive nature of microplastic contamination means exposure occurs continuously through multiple pathways.

Wildlife ingestion of plastic particles causes digestive problems, reproductive issues, and mortality across numerous species. Marine animals mistake plastic fragments for food, leading to malnutrition and internal injuries that affect population sustainability.

Scientific understanding of health impacts remains limited because microplastic research is relatively recent. Long-term studies require decades to document chronic effects, but preliminary findings suggest cause for concern.

Elimination of plastic pollution sources becomes critical for preventing further contamination while researchers work to understand existing exposure consequences.

Agricultural Scientist Pursues Dream of Decomposing Bags

Dr. Janaswamy’s research program targets one of the most problematic plastic products: retail shopping bags. These lightweight items are used once and often discarded carelessly, creating visible litter throughout urban and natural environments.

“That is my dream,” Janaswamy explained about developing plastic-like bags that decompose naturally in the environment. His vision involves replacing petroleum-based bags with agricultural materials that provide identical functionality without environmental persistence.

Retail bags present unique engineering challenges because they must be strong enough to carry heavy loads while remaining thin and lightweight. Traditional biodegradable materials often compromise strength for environmental compatibility.

Agricultural byproducts offer abundant raw material sources that don’t compete with food production. Utilizing waste streams from farming and food processing creates economic value while addressing environmental problems.

The researcher’s systematic approach involves testing multiple plant sources to identify optimal materials for different packaging applications.

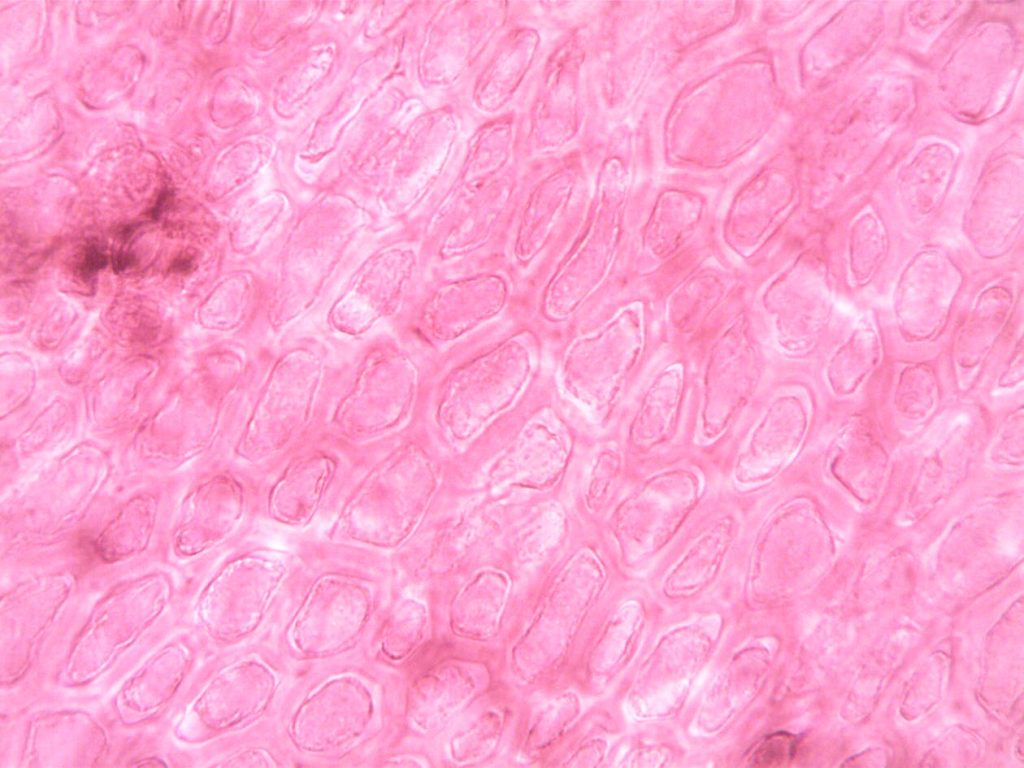

Nature’s Most Abundant Building Block

Cellulose serves as the structural foundation for plant cell walls, making it Earth’s most abundant organic polymer. This biopolymer provides strength and rigidity through hydrogen bonds connecting chains of glucose molecules.

Plant materials humans have used for millennia, including cotton for textiles and wood for construction, derive their properties primarily from cellulose content. These applications demonstrate cellulose’s durability and versatility for creating useful products.

Cellulose extraction from agricultural waste streams provides renewable resources without requiring additional land or water inputs. Processing technologies can isolate high-quality cellulose from materials that would otherwise be discarded.

Chemical properties of cellulose allow modification and processing into films, fibers, and other forms suitable for various applications. Advanced processing techniques enable the creation of materials with specific performance characteristics.

“By extracting cellulose from agricultural products, value-added products can be created,” Janaswamy noted about the potential for transforming waste into commercial materials.

Vineyard Waste Represents Massive Untapped Resource

Annual vineyard management practices generate enormous quantities of pruned material that typically receive minimal utilization. “Every year we prune the majority of yearly biomass off the vine,” Fennell explained about standard viticultural practices.

Current disposal methods for pruned canes include mowing, composting, and burning, approaches that provide limited economic value while sometimes creating air quality concerns. Australian research confirms that removing prunings doesn’t harm soil health when managed properly.

Global wine production creates similar waste streams in every grape-growing region, providing potential feedstock supplies for scaling biodegradable packaging production. Established vineyard operations could supply raw materials without requiring new agricultural infrastructure.

Seasonal timing of pruning operations concentrates raw material availability during winter months when processing facilities could operate efficiently. Storage and handling systems for agricultural materials already exist in wine-growing regions.

Transportation costs remain manageable because processing facilities could be located near vineyard areas, reducing logistics challenges that affect other agricultural waste streams.

Laboratory Process Transforms Canes Into Clear Films

The research team developed standardized protocols for converting grapevine canes into packaging films through systematic processing steps. Initial preparation involves drying and grinding harvested canes to create uniform feedstock material.

Cellulose extraction requires chemical processing to separate desired polymers from lignin, hemicellulose, and other plant components. The resulting cellulose residue resembles cotton in appearance and handling characteristics.

Solubilization converts extracted cellulose into liquid form suitable for casting onto glass plates. Controlled drying creates thin, uniform films with consistent thickness and properties across the material surface.

The research team includes doctoral candidates Sandeep Paudel and Sumi Regmi, plus Sajal Bhattarai from Purdue University, providing diverse expertise for optimizing processing parameters. Published protocols enable other researchers to replicate and refine the methodology.

Quality control testing ensures reproducible results and identifies optimal processing conditions for different applications and performance requirements.

Superior Strength Surpasses Traditional Plastic Performance

Mechanical testing revealed that grapevine-derived films exceed the tensile strength of conventional plastic shopping bags. This strength advantage eliminates concerns about performance compromises when switching to biodegradable alternatives.

Transparency characteristics match consumer expectations for packaging materials that allow product visibility. “High transmittance in packaging films enhances product visibility, making them more attractive to consumers and facilitating easy quality inspection without the need for unsealing,” Janaswamy explained.

Food packaging applications become feasible due to the films’ clarity and barrier properties. Visual inspection capabilities satisfy retail requirements while maintaining product freshness and protection during distribution.

Handling characteristics feel familiar to consumers accustomed to conventional plastic films. The transition to biodegradable alternatives becomes seamless when performance and user experience remain consistent.

Manufacturing processes can potentially adapt existing plastic film production equipment, reducing capital investment barriers for commercial adoption.

Rapid Biodegradation Leaves No Harmful Environmental Residue

Soil decomposition tests documented complete film breakdown within 17 days under standard conditions. This timeframe provides adequate service life for single-use applications while eliminating long-term environmental persistence.

Laboratory analysis confirmed that decomposition products pose no toxicity risks to soil organisms or plant growth. Complete mineralization returns carbon to natural cycles without accumulating harmful byproducts.

Composting compatibility means disposal can occur through existing organic waste management systems. Home composting operations could handle these materials alongside food scraps and yard waste.

Marine environment testing would provide additional data about decomposition rates in aquatic ecosystems where plastic pollution creates the most visible problems.

The 17-day breakdown period contrasts dramatically with the centuries required for conventional plastic decomposition.

Circular Economy Benefits Transform Waste Management

Converting vineyard waste into valuable packaging materials creates economic incentives for proper disposal while reducing environmental impacts. Farmers gain revenue streams from materials previously considered waste products.

Regional processing facilities could support local agriculture while reducing transportation costs and carbon emissions associated with waste disposal. Integrated systems create mutual benefits for farmers and packaging manufacturers.

Reduced dependence on petroleum-based materials decreases vulnerability to fossil fuel price volatility and supply disruptions. Domestic agricultural sources provide more stable and predictable raw material supplies.

Employment opportunities in rural communities could emerge from processing operations and related services. Value-added agriculture supports economic development in farming regions.

Environmental benefits extend beyond plastic pollution reduction to include decreased burning of agricultural waste and reduced pressure on landfill capacity.

Path Forward Requires Scaling and Standardization

Commercial viability depends on developing reliable supply chains for raw materials and establishing consistent processing standards. Industry adoption requires predictable quality and availability.

Food safety regulations must be satisfied before packaging materials can contact edible products. Regulatory approval processes require extensive testing and documentation.

Consumer acceptance depends on price competitiveness with conventional alternatives and familiar performance characteristics. Market penetration requires careful attention to user experience factors.

Manufacturing infrastructure must adapt to handle biodegradable materials throughout production, distribution, and disposal phases. Existing systems may require modifications to accommodate new materials.

International standards development will facilitate global adoption and ensure consistent performance expectations across markets.

Global Implications for Sustainable Packaging Revolution

Successful commercialization of grapevine-based packaging could catalyze broader adoption of agricultural waste conversion technologies. Demonstration of technical and economic feasibility encourages investment in similar approaches.

Climate change mitigation benefits from reduced petroleum consumption and waste management improvements. Sustainable packaging contributes to broader environmental goals while addressing specific pollution problems.

Developing nations with agricultural economies could benefit from technologies that add value to existing waste streams. Rural development opportunities align with environmental protection objectives.

Ocean health improvements require eliminating plastic pollution sources rather than attempting cleanup after contamination occurs. Prevention-focused approaches address root causes more effectively than remediation efforts.

The breakthrough represents concrete progress toward circular economy principles, where waste materials become inputs for new production cycles rather than environmental burdens.